Engineers have developed a new material for nanoscale 3D printing that can absorb twice as much energy and achieve high printing speeds.

Also See: Cohabs Announces €110 Million Investment Round

3D Prints are Getting Much Shorter

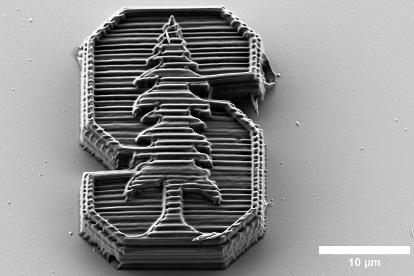

Stanford researchers have developed a new material for fast printing at the nanoscale. With it, they print tiny lattices that are both strong and lightweight. The development could be used to create lightweight protective coatings for fragile parts of satellites, drones and microelectronics. To create their material, the engineers incorporated metal nanoclusters (tiny clusters of atoms) into a printing medium using two-photon lithography. A method in which the printed material hardens as a result of a chemical reaction initiated by laser radiation.

Scientists have discovered that nanoclusters are very good at triggering desired reactions and the result is a material consisting of polymer printing media and metal. The researchers were able to combine metal nanoclusters with various materials for 3D printing. These include acrylates, epoxy resins and proteins. The developers say this means the new method is suitable for use in a variety of fields.

In addition, nanoclusters helped speed up the printing process. For example, by combining nanoclusters with proteins, Gu and colleagues were able to print at speeds of 100 mm per second, about 100 times faster than conventional nanoscale protein printing technologies. The researchers tested their new material with several different lattice structures. The study showed that the new material improved the products' ability to absorb energy, increase strength and recoverability - essentially the ability to compress and spring back.

No comments yet for this news, be the first one!...